Semco SI BCDS 100V 50A 2CH

Product Details:

Semco SI BCDS 100V 50A 2CH Price And Quantity

- 640000 INR/Unit

- 1 Unit

Semco SI BCDS 100V 50A 2CH Trade Information

- 5 Days

- Asia

- All India

Product Description

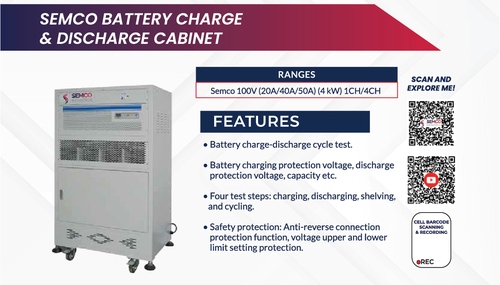

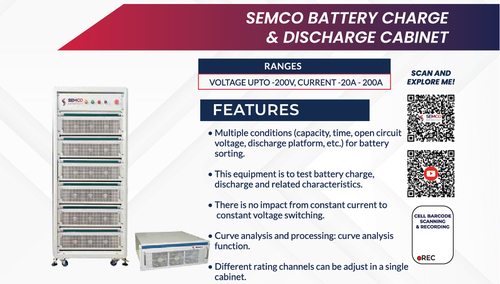

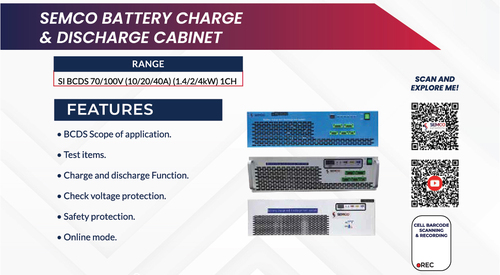

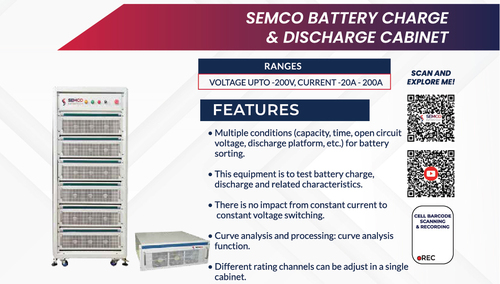

The equipment is mainly used to test battery charging and discharging and related battery characteristics and the test channels are completely independent Through software programming control customers can charge and discharge batteries at any current and voltage within the range of programming

Safety protection the equipment has the functions of output anti reverse connection abnormal voltage sampling line and abnormal current test line detection and protection when the voltage sampling line falls off or disconnects and the current line contacts poorly the equipment detects the abnormality in time and suspends the test channel It has power off protection over current protection over voltage protection and over temperature protection which can ensure the safety of test

The process flow can customize variables to participate in programming realize a variety of combined test schemes and support multiple loop nesting

Single point independence each channel has an independent programmable constant current source and constant voltage source which can independently set the test step operation

Interrupt connection Under any circumstances such as sudden power failure communication interruption or other abnormal reasons after the channel stops the next time the condition is restored the work step has automatic connection and forced connection operation functions

Abnormal capture which can accurately capture the details of voltage and current changes for example when the current and voltage changes beyond a certain range the equipment can automatically generate alarms and suspend tests

Log tracking with log function including records in the whole test process and exception records which can be used for tracing and exception query in the test process

Curve analysis and processing free selection of cycles to be displayed and free combination of various curves

The equipment current output adopts soft start mode to avoid the thermal shock of the battery and connector caused by instantaneous output of large current surge

CC CV charging CC CV has no gap transition and no voltage and current impact during charging process which can prevent PCB protection caused by peak current impact of battery

The charging and discharging steps are started by soft start without current impact at the moment of start and the transition of constant current and constant voltage switching is smooth without spike and sudden wave

Exclusive overcharge protection During the charging process of the battery pack when the protection board is abnormal or other protection boards are disconnected the instantaneous pulse voltage at the protection board end or the battery end will not exceed 10 V

Other Products in 'Battery Comprehensive Tester' category

|

|

|

|

SEMCO INFRATECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |