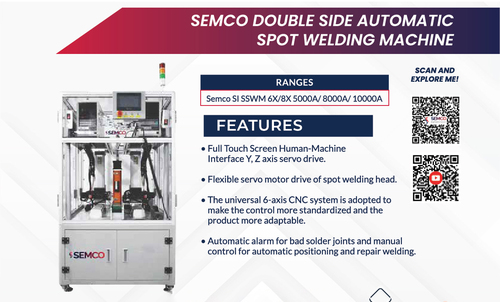

Semco SI DSWM 8X 8000

Product Details:

- Weight 330 Kilograms (kg)

- Power 6KW Watt (w)

- Dimension (L*W*H) 55X43X67 Inch (in)

- Click to View more

Semco SI DSWM 8X 8000 Price And Quantity

- 1 Unit

- 2025000 INR/Unit

Semco SI DSWM 8X 8000 Product Specifications

- 330 Kilograms (kg)

- 6KW Watt (w)

- 55X43X67 Inch (in)

Semco SI DSWM 8X 8000 Trade Information

- Asia

- All India

Product Description

1 Work storm structure, workpiece height and work desktop, easy to operate

2 Suitable for combined spot welding of cylindrical batteries of a variety of 70 mm / 65mm height

3 The platform can use various welding power supplies

4 There is no specific requirement for any design spot welding program route

5 Double weld head can be rotated between 135 degrees and turn on the shut dewer rotation function

6 Visual transparent workstation design is conducive to the observation of welding in time

7 Double Y Z axis servo drive point welding head left and right configuration double sided

simultaneous spot welding weld head flexible servo motor drive The weld head is rotated using an efficient stepper

8 Automatic control spot welding is from sex, production products are neatly drawn

9 Programming is simple and easy to learn and users can design themselves with their own

needs and product The file management is convenient with convenient map function

10 During the spot welding process Welding current detection does not meet the standard automatically suspended and prompting

11 Can operate manual replacement on the machine

12 Configure the dedicated value to the bit tool to adjust the weld head the solder pin is faster

13 Production count

14 Replacing the product only with adjustment energy call up the program no need to operate

15 You can manually operate from a breakpoint from a breakpoint

16 Store dozens of product welding procedures and parameters in the system

17 Welding path CAD map features easy to use

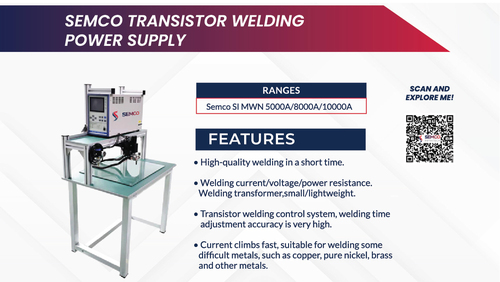

18 Mix the production line system to save the welding data of each group of products to chase This feature is supported when supporting a transistor power

19 Servo drive automatic protection function The equipment is safe to protect the equipment safely when the workpiece driven is too large

Other Products in 'Welding Machine' category

|

|

|

|

SEMCO INFRATECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |