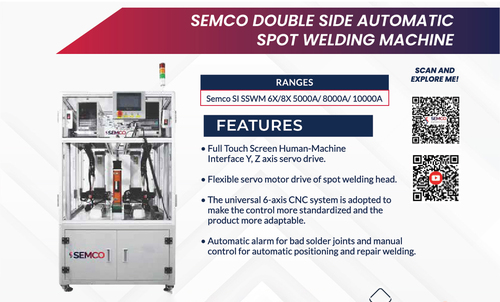

Semco SI DSWM 6X 5000A - Double Side Automatic Spot Welding Machine - Fully Electric

Product Details:

- Condition New

- Dimension (L*W*H) 39X55X66 Inch (in)

- Weight 300 Kilograms (kg)

- Click to View more

Semco SI DSWM 6X 5000A - Double Side Automatic Spot Welding Machine - Fully Electric Price And Quantity

- 1 Unit

- 1720000.00 INR/Unit

Semco SI DSWM 6X 5000A - Double Side Automatic Spot Welding Machine - Fully Electric Product Specifications

- New

- 39X55X66 Inch (in)

- 300 Kilograms (kg)

Semco SI DSWM 6X 5000A - Double Side Automatic Spot Welding Machine - Fully Electric Trade Information

- 10 Unit Per Day

- 5 Days

- Asia

- All India

Product Description

1 Adopt a universal 6 axis numerical control system to make the control more standardized and the product more adaptable

2 Full touch screen man machine interface Full Touch Screen Human Machine Interface

3 The welding head is driven by a flexible servo motor Y Z axis servo drive double sided X1/X2 axis spot welding at the same time flexible servo motor drive of spot welding head

4 Workstation design is oriented to the production site with simple operation and setting low operating threshold easy to learn and use

5 Equipment with Semco Customer Selection Welding Power Supply This project is an optional project It can be equipped with several welding power sources some of which have different functions due to different welding power sources Special welding power supply can also be selected individually

6 The dual welding heads are convenient to manually change the direction which solves the problem of the different horizontal and vertical cut angles of the solar cells need to be customized

7 The spot welding program route can be designed arbitrarily without specific requirements

8 After programming the coordinates of each point can also be accurately corrected

9 Automatic alarm for defective solder joints manual control and automatic positioning repair welding some functions when equipped with monitoring function welding power supply

Other Products in 'Welding Machine' category

|

|

|

|

SEMCO INFRATECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |